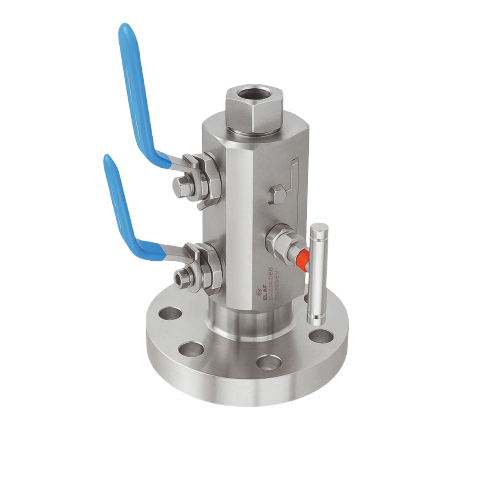

The ELAF DBB Monoblock (Ball–Needle–Ball) valve is a compact, single-body Double Block and Bleed (DBB) solution designed for maximum safety and efficiency. It integrates two ball valves for double isolation and a central needle valve for cavity venting within a single forged body. This monoblock construction eliminates multiple leak paths, reduces weight, and provides a cost-effective alternative to conventional multi-valve assemblies while ensuring superior integrity in critical service applications.

Need a custom size or material? Contact ELAF Valves for tailored configurations.

Get a Quote